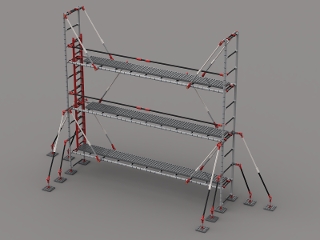

Scaffolding contains some set of requirements. The first set is to create safety for workers in the working area and also production. Then providing permission to goes to a higher level in working areas. The last set is to point the loads or to carry areas.

Basic components

Stored parts are moved to the site then transported to ensure complete efficiency as well as operational cost-effectiveness. Small components range is lower the investment cost and also increase the utilization rates. In some scaffold systems, few components are only needed economically and to divers the range extremely in Scaffolding Enfield operations. In this world, different types of scaffolds are used for particular purposes. They are access scaffold, working scaffold, reinforcement scaffold, facade scaffold, and shoring. These types are tested with some safety features that allow similar components to use as a stair tower, shoring, working platforms, and reinforcement scaffold. Some other applications are also possible to use. It shows that on-site material is automatically decreased and increases the utilization rates. Safety levels and efficiency are extremely carried out in construction progress.

Shoring

When building in repairs or alternations or danger at the time shoring process is used. It is to support the building or structure or trench with shores. The process comes from a metal prop or shores a timber. It can be horizontal or angled or vertical. If shoring is used on construction sites then it is very easy. Proper static verification is needed for towers and must have prepared a list for all heights. Its base width range is 1.5 m to 3 m, 50 cm is for rectangular or square to the ground. Geometrical adjustments and cost-effective bearing capacity are achieved by this process. From this form, 10 different towers broad range is achieved and realized. Per leg 40KN load is carried for every height also. Basic shoring towers are assembled by different cross-sections.

Working Scaffold

It was a temporary structure that was used to support materials and work crew to add in maintenance, construction, and also repairing in buildings. Adjustments with width and longitudinal are done with 50 cm increments only. Secrete information for usage in the safe assembly is included in every tower with the help of erection instructions. Tension proof connection is to join every standard with each other, the crane moves the complete platform units which is called as connections. Easy and simple extensions allowed by kit principle to make the required levels. Quantities of materials are ordered and determined quickly.

Reinforcement Scaffold

For construction sites, only extremely stable units are delivered that don’t need to move blast or anchors, and repositioned are fine without any modifications. Erection instructions are also provided for reinforcement scaffolding that contains all safety guidelines with the inclusion of crane attachment points. Already heights are required for the configuration of scaffolding units while doing formwork planning.

There are some application possibilities like closing the formwork, placing of formwork ties, reinforcement work, and concreting. Some users only have the approval to generate scaffolding equipment at soy cost. Therefore every type of scaffold has unique features that are used only for a certain purpose. Comparing the types of Scaffolds is simply a waste of time. So every scaffold type is something special and unique.